Maintaining a 3D printer can be the difference between consistent, high-quality prints and a frustrating series of failed attempts. One of the most effective maintenance techniques is the “cold pull,” also known as the “atomic pull.” This method is particularly useful when dealing with filament blockages and ensuring the printer’s hotend remains clean. In this post, we’ll dive into what a cold pull is, when you should perform one, and how to execute the process step by step.

What is a Cold Pull (Atomic Pull)?

A cold pull is a technique used to clean the hotend of a 3D printer by pulling out filament at a lower temperature. This process removes blockages, debris, and filament residue that may have accumulated inside the nozzle. Unlike other methods that may require taking the hotend apart, a cold pull offers a less invasive and effective solution.

The reason this method is effective lies in the behavior of filament at different temperatures. By pulling the filament out at just the right temperature—where it’s solid but still pliable—you can extract debris lodged in the nozzle. This technique helps avoid clogs that could disrupt print quality or cause failed prints.

When Should You Perform a Cold Pull?

A cold pull is a useful maintenance technique that can address several issues and should be part of any 3D printer owner’s toolkit. Here are a few situations when a cold pull is necessary:

- Frequent Under-Extrusion: If your printer is struggling to extrude filament consistently or leaves gaps in your prints, it may indicate a partial clog that a cold pull can fix.

- Inconsistent Layer Formation: Visible inconsistencies in layer formation or print quality could be caused by small obstructions in the nozzle.

- Filament Grinding or Load/Unload Problems: If the filament has trouble feeding through the hotend or gets chewed up by the extruder, a blockage could be present.

- After Using Certain Filaments: Some materials, like PLA and PETG, can leave residues that gradually build up. Performing a cold pull after using these filaments can help maintain the nozzle’s cleanliness.

Integrating cold pulls into a regular maintenance schedule is also advisable, especially when printing with filaments that are known to leave residue or after extended print sessions.

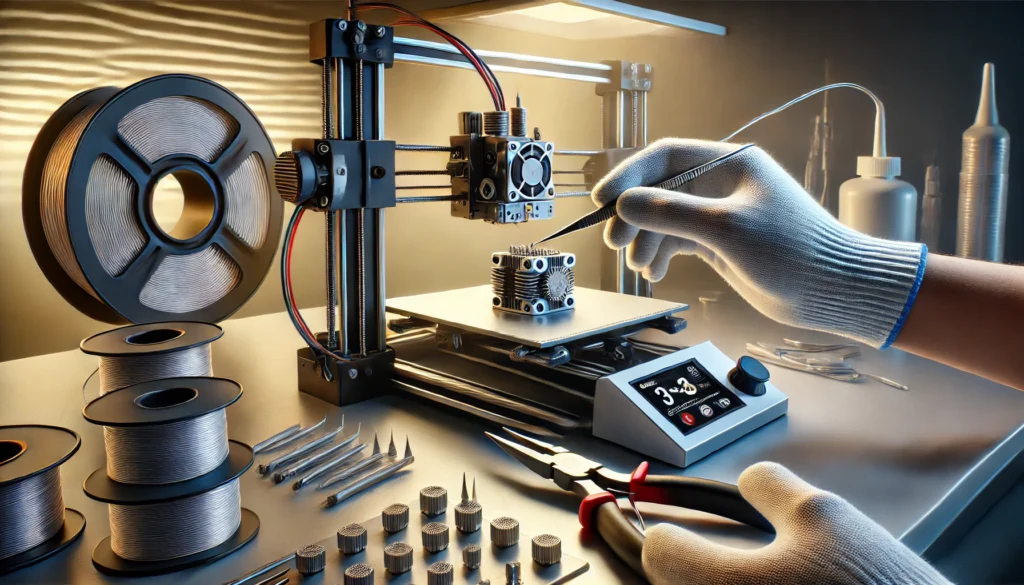

Tools and Materials Needed

Before performing a cold pull, gather the following tools and materials:

- Needle-Nose Pliers: Useful for gripping the filament during the pull.

- Clean Filament: Nylon is ideal for cold pulls due to its strength and pliability at lower temperatures. White PLA can also be used if nylon is unavailable.

- Thermal Gloves (Optional): For safely handling the filament and hotend when it’s still warm.

Step-by-Step Guide to Performing a Cold Pull

- Heat the Hotend

Begin by heating the hotend to the standard printing temperature for the filament currently loaded. For example, set the hotend to 210°C if you’ve been printing with PLA. This will ensure that any remaining filament inside is fully melted. - Insert and Load the Cleaning Filament

Once the hotend reaches the target temperature, insert the cleaning filament (such as nylon) and feed it until it extrudes cleanly. This helps push out any partially melted filament and prepares the hotend for the cold pull. - Cool Down the Hotend

Lower the hotend temperature gradually to a range where the filament becomes solid but remains pliable. For PLA, this is typically around 90°C. For other filaments, adjust accordingly:

- Nylon: 110-120°C

- ABS: 120-140°C

- Perform the Cold Pull

With the hotend at the correct temperature, grip the filament using needle-nose pliers or your hand (if wearing thermal gloves) and pull it out of the hotend with a firm, steady motion. Inspect the tip of the filament for debris, filament residue, or particles that may have been lodged in the nozzle. - Repeat if Necessary

If the filament comes out with visible debris, repeat the process until the filament tip appears clean. This may take a few attempts but ensures that the hotend and nozzle are clear of any obstructions.

Tips and Tricks for an Effective Cold Pull

- Adjust the Temperature Range: The key to a successful cold pull is finding the right temperature. Too hot, and the filament will stretch without pulling debris. Too cold, and it may snap off.

- Experiment with Different Filaments: Nylon is often the preferred material due to its flexibility and strength, but other options like ABS or PETG can work if you match the temperature range correctly.

- Post-Maintenance Check: After completing a cold pull, visually inspect the nozzle and extrude a small amount of filament to ensure that it flows smoothly. This quick check will confirm that the blockage is resolved before resuming your prints.

Preventive Measures to Minimize Blockages

While cold pulls are an effective solution for dealing with clogs, taking preventive measures can reduce the frequency of such maintenance:

- Regular Maintenance: Incorporate cold pulls into your routine maintenance schedule, especially after long print sessions or when switching filament types.

- High-Quality Filament: Low-quality filament is more likely to leave residues or contain impurities that clog the nozzle. Investing in high-quality filament can significantly reduce the likelihood of blockages.

- Hotend Cleaning Accessories: Consider other tools like nozzle brushes or cleaning filaments designed to maintain your printer’s hotend. Using these tools regularly can help maintain the nozzle’s condition without needing frequent cold pulls.

Conclusion

Cold pulls are an essential part of 3D printer maintenance, offering a straightforward and effective way to clean the hotend and ensure consistent print quality. By following the steps outlined above and incorporating cold pulls into your routine, you can prevent major clogs and keep your printer running smoothly. Regular maintenance, high-quality filament, and the right tools will ensure that your 3D printing experience remains hassle-free.

By understanding when and how to perform a cold pull, you’ll have one more powerful technique in your arsenal to keep your 3D printer operating at its best. Happy printing!